Finishing

Using our in house machinery, we add the finishing touches to your projects to make sure your job is of the highest quality; if we aren’t proud of it, then it doesn’t leave the building.

Enquire TodayFinishing Services We Provide

Finishing is a term used in the print industry to describe the processes that take place after sheets have been printed.The most fundamental of these processes is the trimming of the sheets, but also extends to lamination, encapsulation, gluing, stitching or stapling of sheets, as well as collating, punching, binding and booklet making, perforation, sequential numbering, progressing to more complex techniques like hot foiling, spot UV, embossing and debossing.

One or more of these processes can be utilised to achieve the desired look, feel and finish for your job.

As the most fundamental process in finishing, trimming takes place on every job, initially to prepare the sheets for printing and, where necessary, working sheets are trimmed to allow further finishing processes to be utilised. The last stage of the finishing process is the final trimming to finished size ready for packing.

A crease or score is added where necessary in order to create a point at which the sheet can be folded cleanly by forming grooves which facilitate a sharp and straight fold in the sheet. Creasing is especially important on heavyweight stocks, where folding may not be as easy or accurate to achieve without the crease.

Folding sheets can create separate panels in order to layout large amounts of information in a clear and readable way for example, takeaway menus or to make sheets easier to handle, such as folding letterheads to fit into envelopes and leaflets folded to insert into display racks.

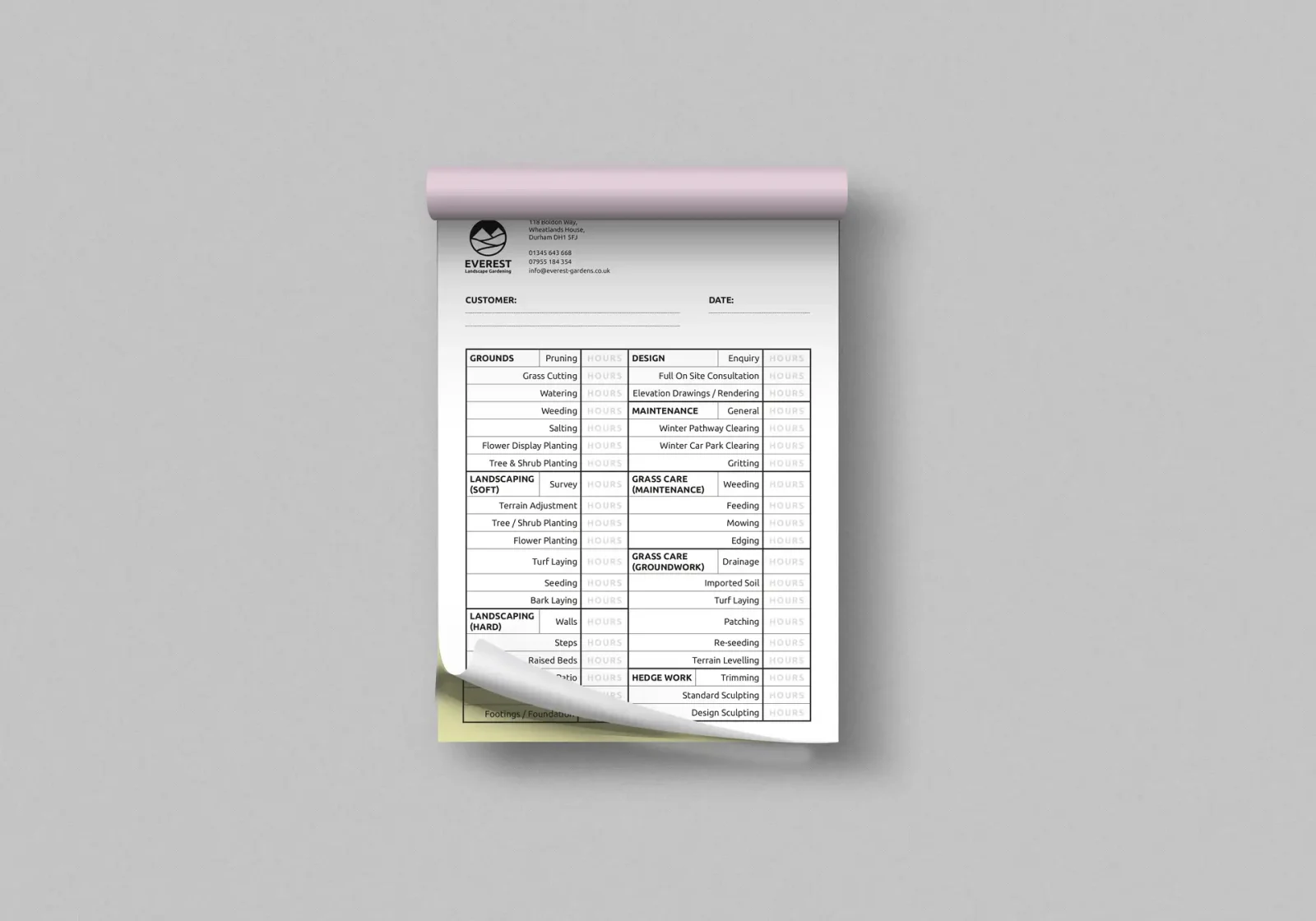

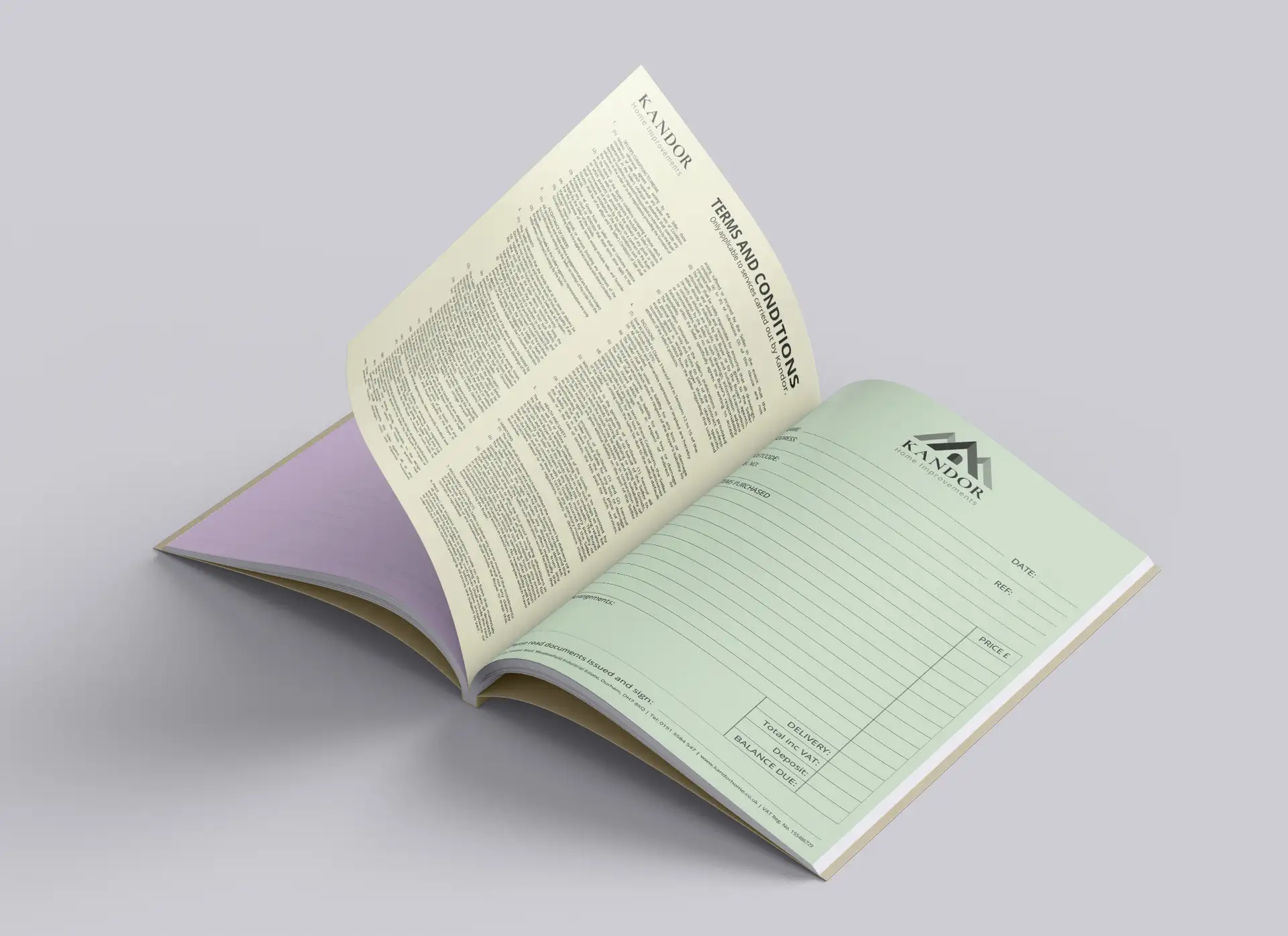

Collation is the gathering and organising of sheets into a predetermined sequence and is used to create NCR sets for forms, or to collect bunches of leaflets into a specific group ready to insert into folders. Collation can also be utilised to gather sheets into order for folding and stitching when creating booklets.

Bonding a film onto flat sheets can increase durability or add visual interest and is ideal for sheets that will be handled often or need to be wiped clean. Laminating films are commonly available in gloss, matt and soft touch finishes, allowing us to achieve the look and feel that you are aiming for.

Encapsulation is the process in which both sides of a printed sheet are secured inside a plastic film to provide extra protection and durability. Various thicknesses of film are available to give the appropriate level of rigidity for the intended purpose of the job. A sealed border is left around the printed sheet, fully encasing it, making the finished product waterproof and is therefore the ideal finish for menus, signs and items that will be regularly handled.

Die-cutting uses a purpose made custom shaped blade, which is bespoke for each job, to allow cuts and creases to be made on any substrate. In order to cut out multiple items of identical shapes and sizes, dies can be created for both simple and complex profiles, making die-cutting an ideal way to create flat sheets for items such as tags, masks or nets for packaging.

Kiss-cutting is a similar process to die-cutting, however the cut is only made through part of the material; for example, labels with a backing sheet would only have the self adhesive face layer cut through, leaving the backing sheet fully intact, allowing the user to easily peel off the label from the backing as required.

Perforating refers to the process of creating small holes in a paper or cardstock, usually along a straight line to allow a portion of the printed item to be easily detached by hand. Some applications require a perforation that tears apart easily, known as a micro-perf. Other applications require a perforation that takes more force to separate, known as a macro-perf.

Numbering can be utilised to ensure that each printed sheet has a unique identifier, making it an ideal security feature of tickets and vouchers, or for multiple part documents where paperwork needs to be retained and traceability is necessary for conformance and regulatory needs.

Paper drilling is a method of creating round holes in multiple sheets of paper. Hollow drill bits of various diameters are used to remove material, thus creating clean and precisely placed holes according to job specification. For example, where sheets are to be added in a ring binder.

Punching is a method of creating a series of holes in multiple sheets to facilitate them being bound together with combs, wires etc. or to be inserted into ring binders. Punching ensures that the holes in a set of sheets are perfectly aligned.

There are various types of punches available in order to create different cutouts in the sheet, such as thumb, 3:1 pitch, 2:1 pitch, square, round and rectangular.

Various specialist adhesives are applied to secure multiple sheets together with a flexible glue, either so that sheets can easily be removed, for example in notepads, or where NCR forms are held together in their respective multi-part sets.

Edge painting is a process of applying coloured inks or foils to the edge of the job. We would recommend that edge painting is applied onto thicker cardstocks as this allows for maximum visual impact.

Bindery Finishing Services

Using the necessary production tools and processes in order to combine pages into a single bound piece, binding can be utilised to create various finished forms of multiple page printed material.A method of creating a book where the inner pages are glued into a soft cover, with a square spine that can be printed on, giving your publications a professional look. Perfect binding is ideal for all books over 1mm thick, but is ideally suited to producing thicker books and brochures, manuals, magazines, reports and catalogues.

By gathering together printed sheets and stapling them through the centre fold, we can create a professional looking booklet. With this binding method, inner pages are securely attached to the cover to give a neat finish that is ideal for catalogues and product lookbooks.

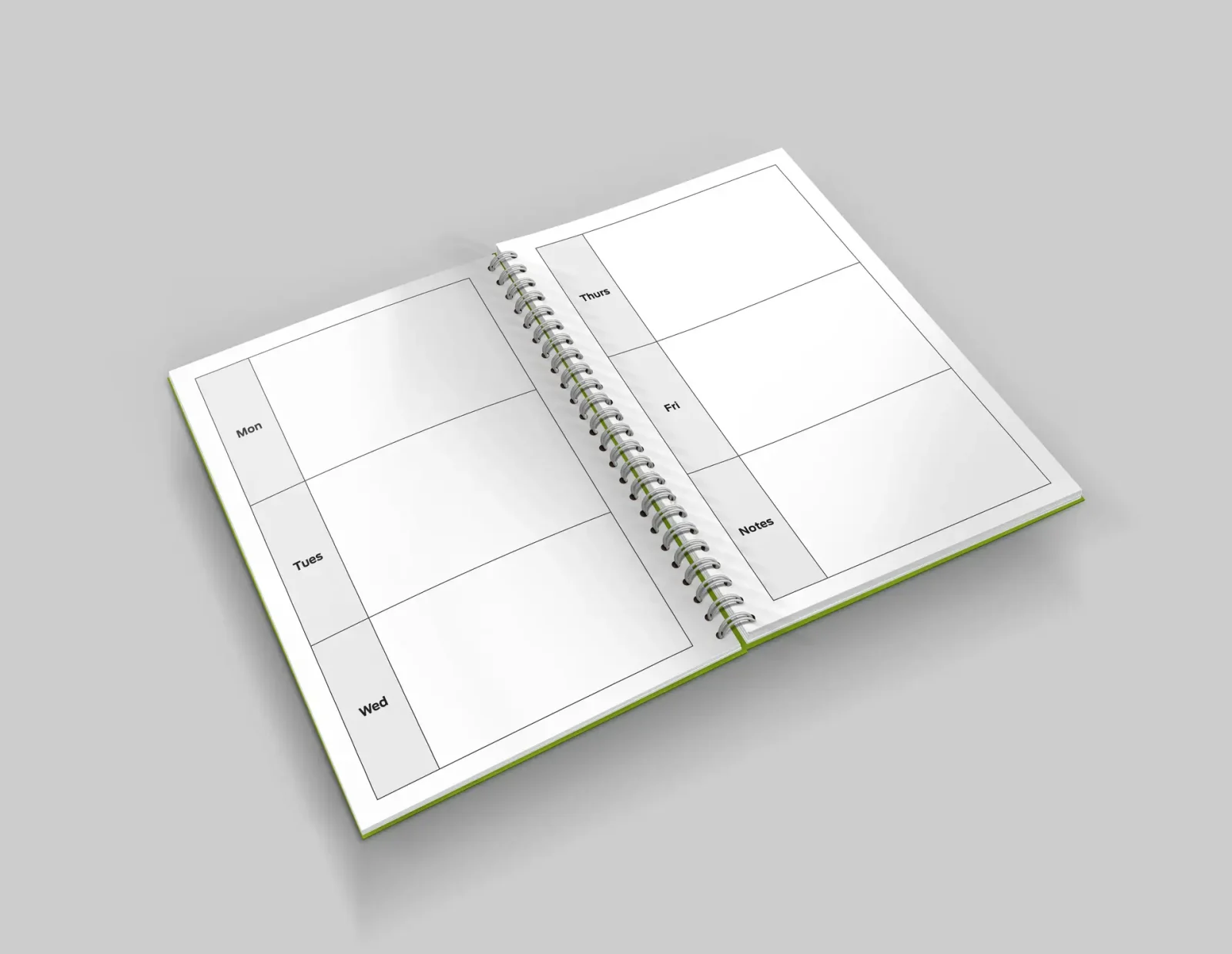

Ideal for presentations and reports, this is a form of binding that allows the sheets to lie flat by using a plastic comb, plastic spiral or metal wire binding to hold together the edge of multiple punched sheets.

Multi page documents can be bound with various thicknesses and profiles of wire, referred to as a “stitch”. The finished appearance of the stitch can be varied; from a flat stitch using a round profile wire, most commonly seen in a booklet or brochure; to a loop stitch, for use in securing the document in a ring binder. A single corner stitch can also be added both horizontally or vertically to multi page documents for easy opening of the sheet to one side, or a much thicker collection of sheets can be stitched using a flat profile wire with heavy duty stitching machinery.

Securing multiple sheets together can be achieved by introducing a punch hole and applying a piece of binding hardware from the wide variety of available options, such as metal/plastic binding screws, split rings – key rings, ball chain, nylon security loops, cable ties, swatch fasteners and snap studs.

Sheet Embellishments Finishing Services

Specialist finishing processes undertaken to increase the look and feel of the final printed sheet, adding value to your printed job.Foil can be adhered to the sheet in various ways to create distinct metallic, holographic and matt film effects. These can be applied to create a luxurious and elegant finish to items such as invitations, tickets and business cards. Foil effects can also be utilised to add security elements to a product to make fraudulent duplication difficult, if not impossible.

A clear polymer coating can be applied to specific areas on a printed sheet in order to create a glossy area to highlight a specific area of the job. It can also be applied to an unprinted area of the sheet in order to give a more subtle effect. When used in conjunction with matt lamination of the printed sheets, this finishing process gives maximum effect to highlight and convey quality to a finished piece of work.

Varnish applies a coating either during or after the print run in order to enhance the visual appeal of the printed sheet, or to add resistance against scuffing or scratching on jobs with a high level of ink coverage.

These two processes are very similar to each other however they have the opposite visual effect. Positive and negative stamping and receiving plates called dies are used to create this effect. Embossing creates a raised impression in the sheet, whereas debossing depresses an image. This results in a tactile, three dimensional effect which can add a luxurious feel and can be particularly effective when used in conjunction with other embellishments like foiling.

Finishing

Enquiry

Contact

"*" indicates required fields