Print Services We Provide

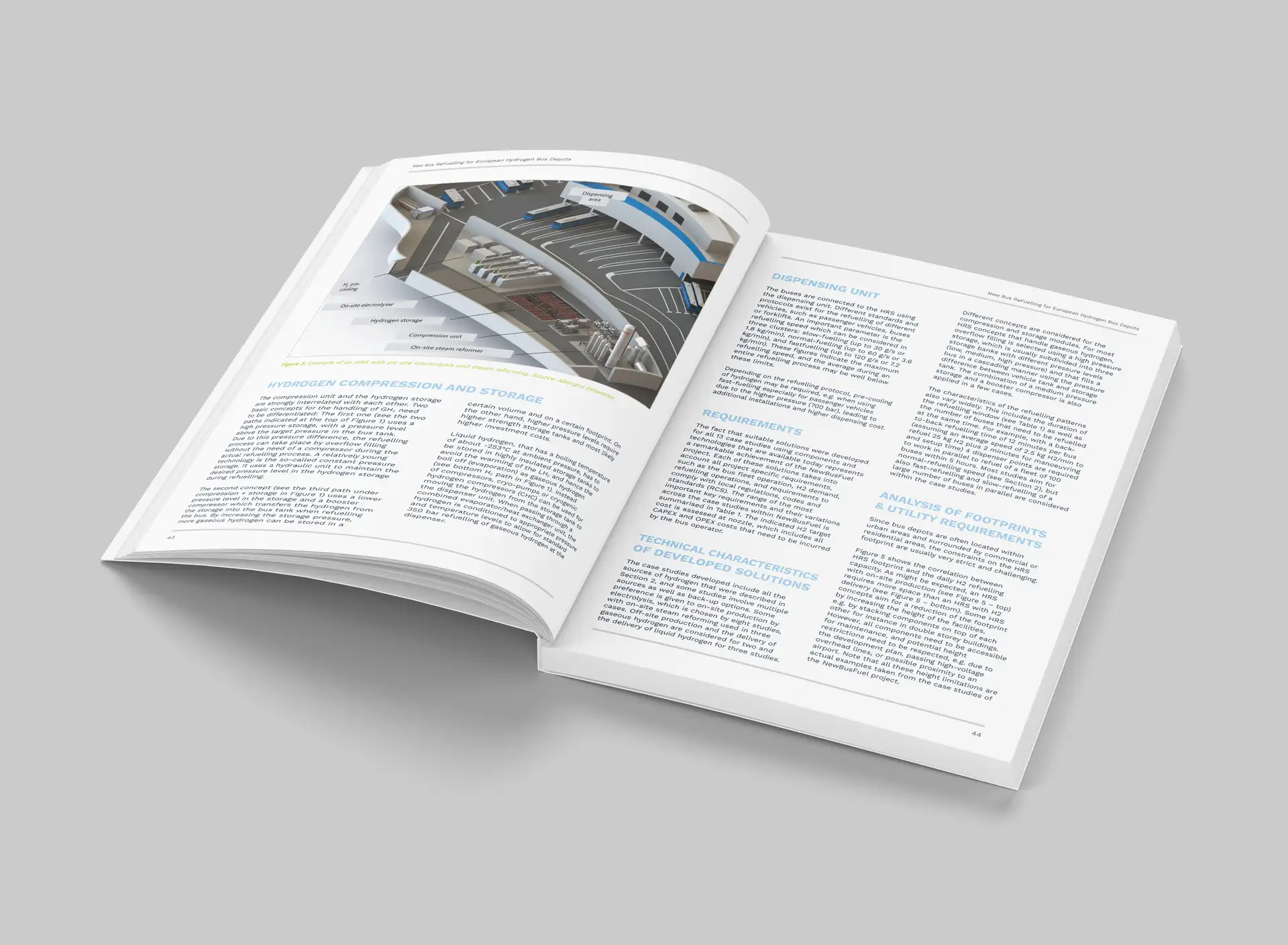

Our team will use their knowledge to advise the most suitable print production method for your project, ensuring a cost effective way to achieve the best quality production outcome.With both digital and litho capabilities, we have the ability to produce any quantity from 1, up to and over 100,000+. Broadly speaking, our digital press is suited for short to medium run lengths and allows for personalisation and variable data to be produced in a high speed, versatile and print on demand environment; whereas our 5 colour lithographic press is ideal for longer run lengths and where spot and speciality colours specific to your brand, such as at the Pantone colour matching system, are required.

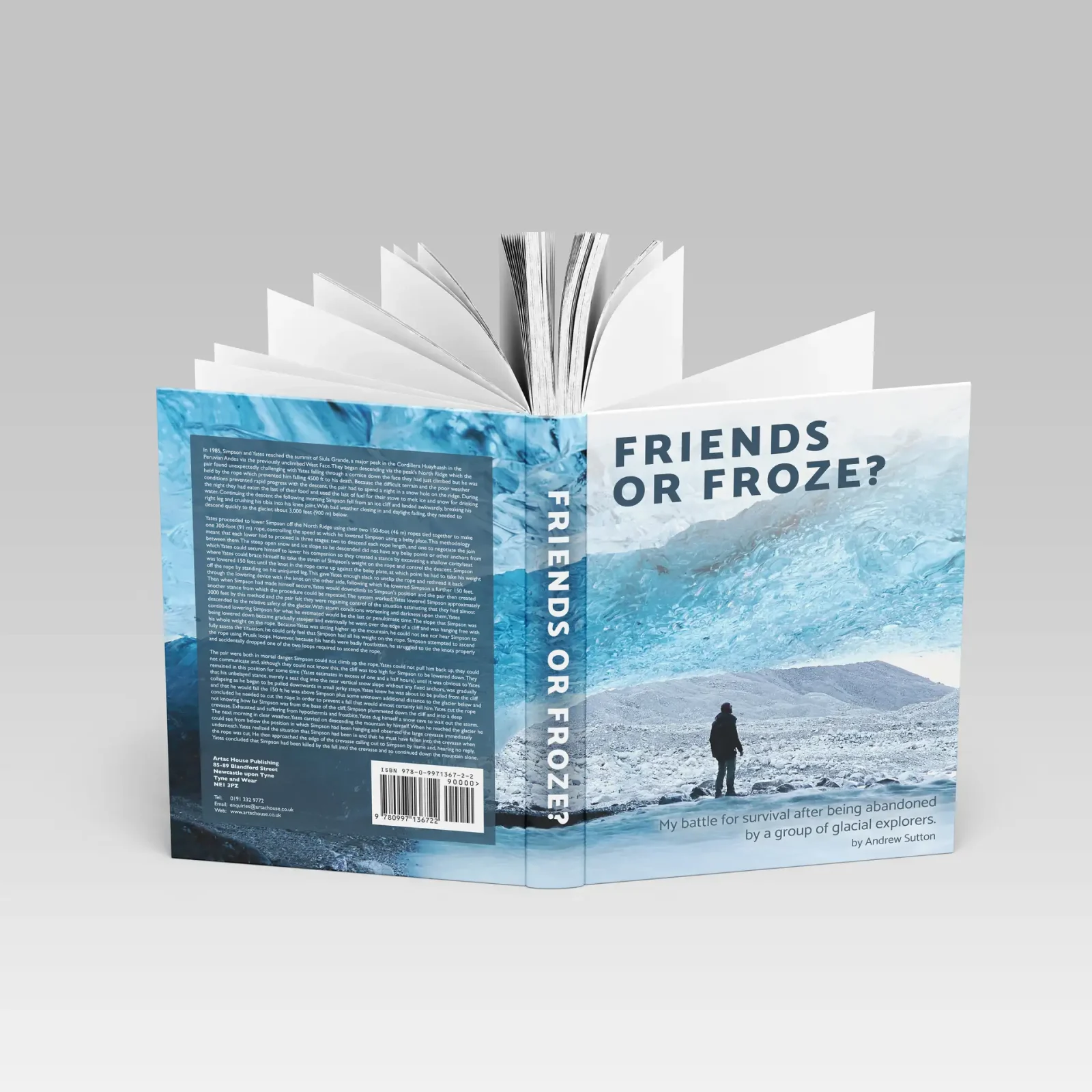

Utilising our five colour lithographic press, we are able to produce an extensive range of high quality printed sheets on a multitude of stocks. Owing to the set up of the machinery, “litho” printing is generally suited to longer quantity runs, however, it can also be used to take advantage of speciality inks and colour specific spot colours, such as the Pantone colour matching system.

Our state of the art digital press ensures that we can reliably produce a wide variety of quantities on various stocks. Digital machinery is not associated with the same initial set up costs as the more traditional print methods, allowing for shorter runs to be more cost effective. Due to the machinery utilising dry toner over conventional wet inks, sheets can be finished immediately after being printed, therefore digital print is ideal for those jobs which may require a quick turnaround.

We can produce an extensive range of large format products such as posters, banners, floor & window stickers, display boards and signage on a wide variety of materials, which can be used internally or externally depending on your end use requirements.

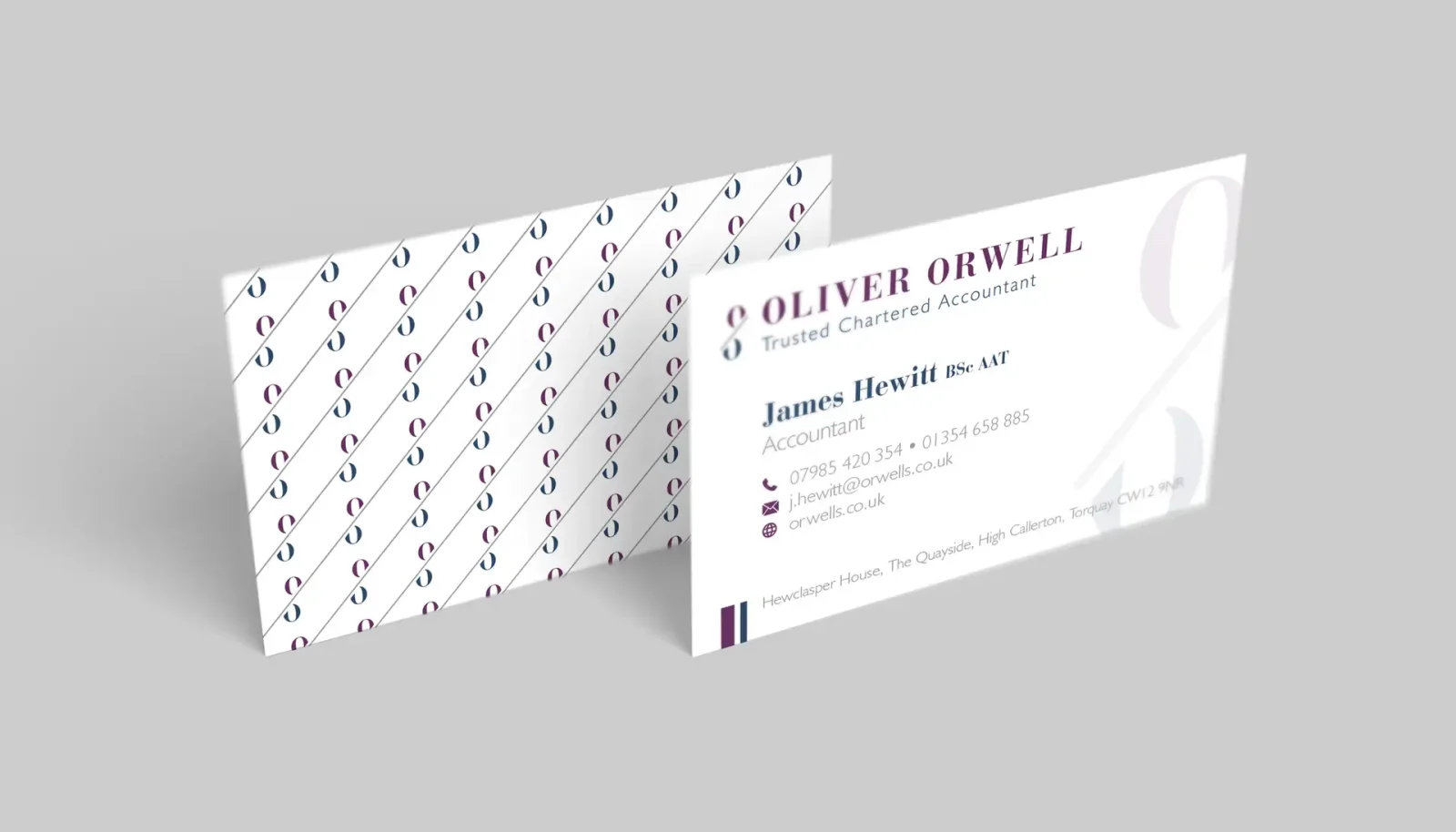

When colour accuracy is particularly imperative to your brand, or you would like something with speciality inks, such as neon colours or metallics, we use industry standard spot colours (Pantone Colour Matching System) to maintain consistency with our litho print.

Owing to differing production methods, the CMYK colour gamut is utilised by our digital presses to print from spot colour files, but if you have a spot colour reference, we will make sure our digital reproduction matches as closely as possible and we are happy to provide you with a printed sample.

Our digital press has the capability to print not only traditional full colour process CMYK, but also additional embellishments; white, silver, gold, clear, fluorescent cyan, fluorescent magenta, and fluorescent yellow. These enhanced capabilities allow your print to grab even more attention, opening up possibilities previously not available to digital print – for example; adding a clear security overlay for numbered vouchers, elevating invitations for special events using the metallics and fluorescent colours, and utilising the white as an underlay to allow for printing colour on dark coloured card and digital stocks.

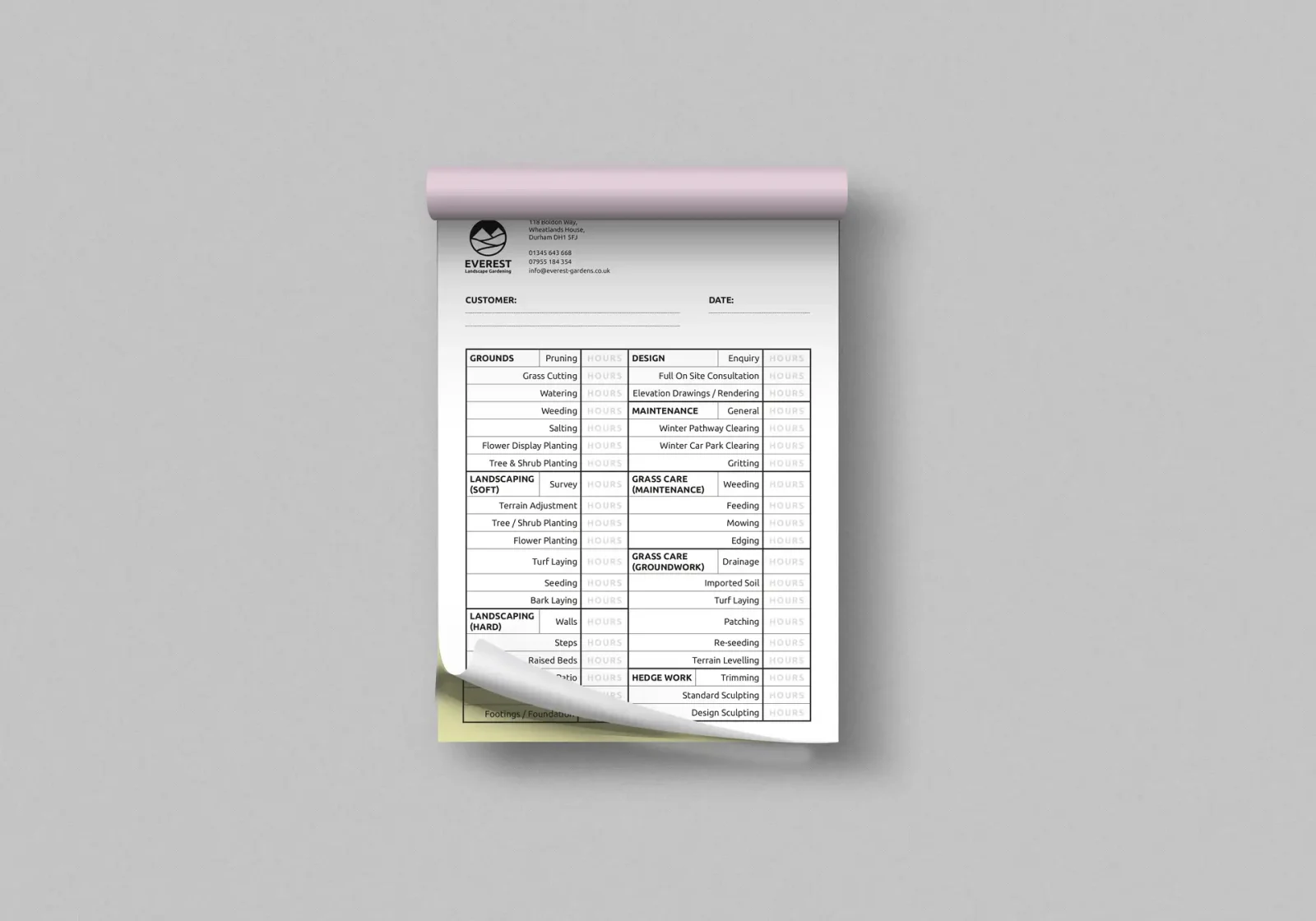

If you need a variety of information printed on a job, variable data printing allows elements to be changed for each impression, and is beneficial for things such as; sequential numbering of tickets and vouchers, printing individual names on invitations and certificates, to creating fully personalised booklets and reports.

Traditionally, letterpress would be printed without leaving an impression indented in the cardstock. Nowadays, it has evolved to give a more tactile quality to print, for a luxurious feel to your projects.

Thermography is a technique used in printing to create a raised impression by fusing a powder to wet printing ink using heat in a specialised process, leaving a textured effect to the print. There are several types of powder available to give different effects as desired.

Enquiry

Contact

"*" indicates required fields